What is it? and why has it entered the marine fuel debate? CNSL is a waste-derived and renewable material with large-scale availability, but it has significant technical challenges. Download the bulletin to understand the full picture.

Our extensive laboratory testing has shown that preventative treatment of MGO with Octamar Winterflow ensures continued fuel flowability, pumpability, and filterability,thus protecting the vessel’s fuel system.

Chemical contamination of residual Fuel Oil can lead to operational problems on the vessels and cause environmental contamination. Fuel additives cannot resolve the issue directly but are part of a commonly used solution.

This bulletin offers practical advice to support the integration of biofuels into vessel operations. It aims to assist managers in maximizing the benefits of biofuel use while maintaining safety, efficient, and being environmentally friendly.

The Mediterranean Sea is one of the highest density shipping routes in the world and will become the 5th emission control area in 2025. Are you ready?

Download the first of a two-part series on Biofuels. Part one explores the reason for widespread demand and the challenges surrounding their long-term usage.

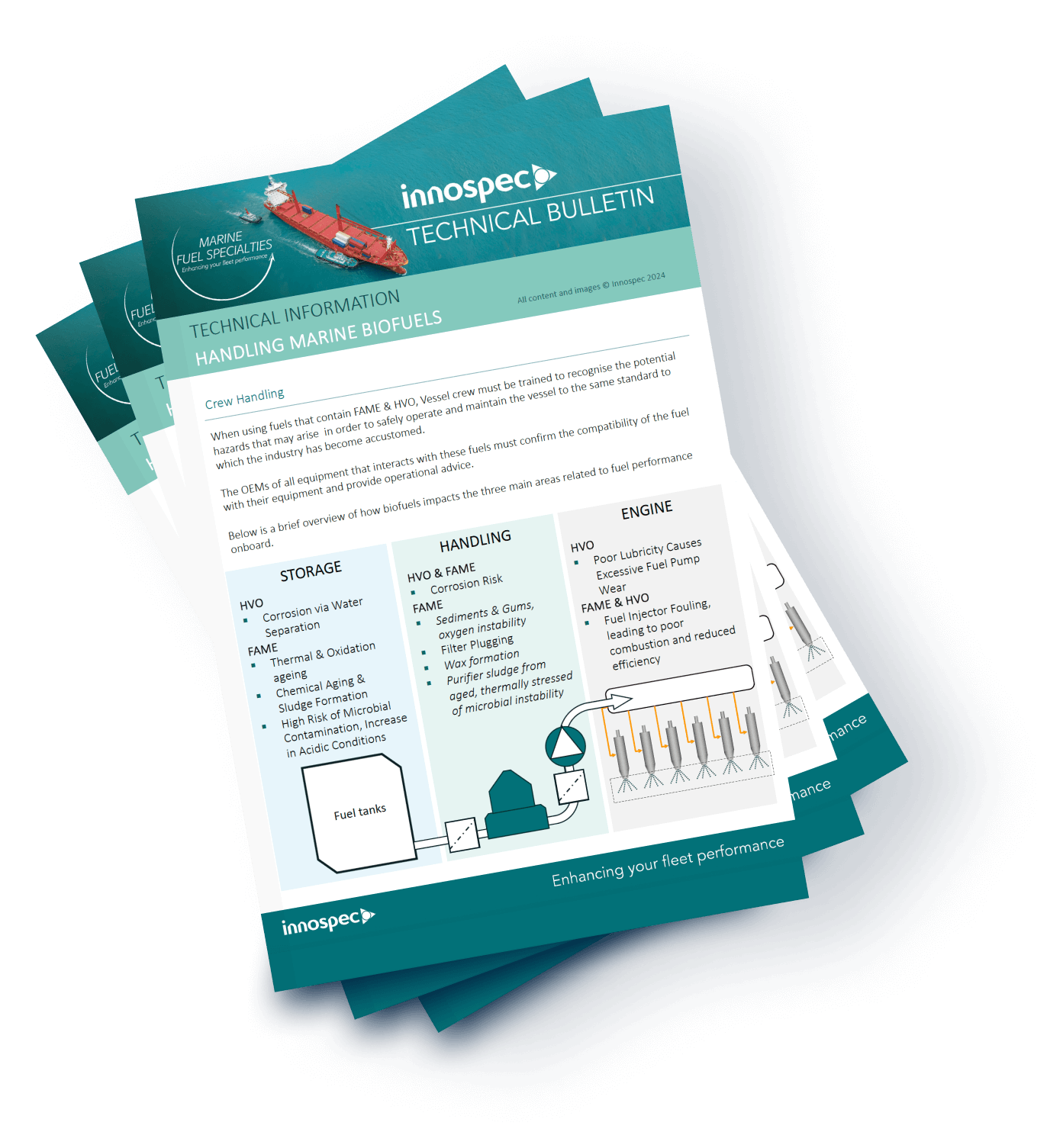

Download the second of a two-part series on Biofuels. We cover how vessel crews need to be trained on biofuels, alongside best practice and real-world examples.

This site is designed to share news, insights, trends and analysis from the marine industry. It includes information gained in the laboratory and the field. World leading experts with technical, scientific and customer facing backgrounds contribute their knowledge and experience in the spirit of collaboration.

Innospec is one of the world's largest suppliers of marine fuel additives. Our focus is on improving fleet performance whatever type of residual fuel is being used. Through continual innovation we strive to improve operational efficiency and reduce fleet costs. The benefits of a stable fuel with a better combustion profile and combustion efficiency are proven to impact fuel economy directly. Perhaps more importantly, efficient combustion reduces the emissions of substances harmful to human health and the environment.

The performance of our Octamar™ range of combustion catalysts, which includes Octamar™ Ultra HF, Octamar™ Complete, and Octamar™ F35C, has been recognized by the leading ship classification society ClassNK. The range has been awarded an Innovation Endorsement for Products & Solutions.

After decades of fleet trials, test bed data and laboratory analysis, it is clear the potential benefits of this technology extend beyond fuel economy. Octamar™ not only optimises engine reliability and boosts engine performance, but it also reduces maintenance requirements and harmful emissions.

ClassNK reviewed the specification and the documents that contain Octamar™ cuts down on piston fouling, improves the cleanliness condition and efficiency of the turbocharger and economiser and reduces unburned carbon deposits in the exhaust system. Particulate Matter, a key driver in post-combustion deposits, black smoke, carbon and other harmful substances is significantly reduced. Improving fuel economy also reduces CO2 emissions.

Biofuels are being considered as possible replacements for today's marine fuels, particularly in older fleets. FAME (Fatty Acid Methyl Esters) Biodiesel, derived from renewable sources, is seen as a potential 'drop in' solution. However, like VLSFO, these fuels present their own set of challenges in a marine environment. Thanks to our in-depth knowledge of biofuel treatment, gained over many years, we ensured our Octamar™ products were developed from the outset to be 'biofuel ready'.

Receive more information on our advanced fuel additive range including product datasheets, presentations or to talk to one of our Technical teams in your region, simply complete your details on the right.

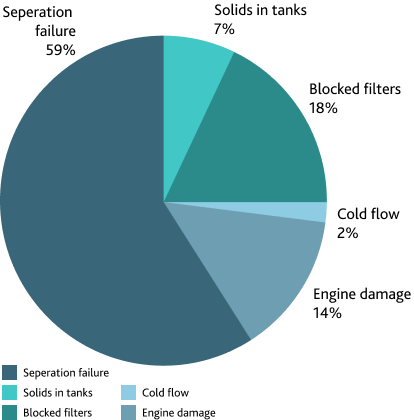

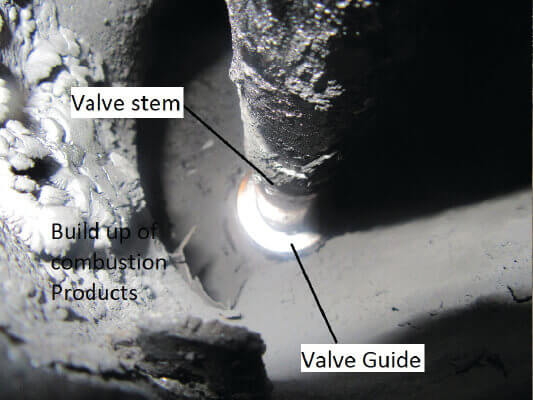

Engine Damage

Handling

Storage

Innospec works with industry groups to verify and independently test the range of products.

ISO for the development of the Classification & Specification of Marine Fuels. ISO8216 and ISO8217.

International Council of Combustion Engines (CIMAC) working group 7 (Fuels).

Lloyds Register, have independently verified the claims associated with Innospec products under rigorous conditions, providing assurance that the product performs.

Class NK verified that Octamar™ products leading to the issuance of an Innovation Endorsement certificate 2022.

Singapore Shipping Association (SSA) marine fuel committee - world largest bunkering port.

There are vast differences in VLSFO on the market and the quality varies from port to port and batch to batch. Although these fuels are all classified under the same specification, they cannot be stored, handled or heated in the same way.

There are:

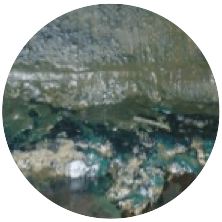

These images show just what can happen. This VLSFO was supplied well within ISO 8217 specification.

It was loaded into completely clean tanks and fuel system, yet failed within four hours. Total engine failure soon followed. This case is not a one-off. There have been a number of reports of fuel system failure and engine damage when using ‘on spec’ fuels.

In the last year, both in the laboratory and in the field, we’ve seen outstanding results with Innospec’s Octamar™ range of products. Examples include:

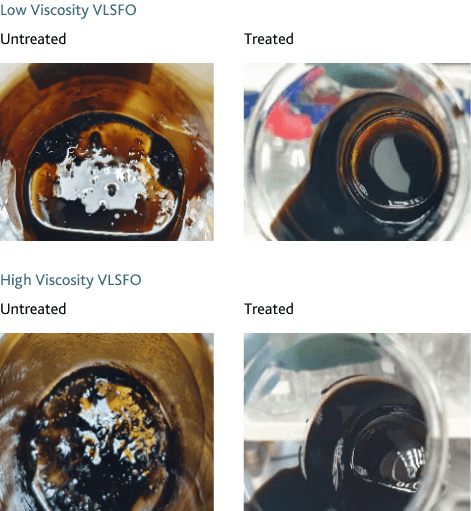

Laboratory images show two fuels, one low and one high, that have been heated to 100°C for 24 Hours. The liquid was then removed and here you can see the sedimentation, aged paraffinic and residual content. Once treated the same fuels are able to withstand stress and remain homogenous.

In the field we have helped hundreds of customers treat fuels to optimise the conditions onboard. Less, sludge, means less wasted fuel, less unplanned maintenance and defects,

and better conditions for the crew.

By pre-treating VLSFO you can solve the problem of fuel instability and tank mix incompatibility. Innospec's Octamar™ range are the only additives that protect against both distillate sludge and asphaltene sludge.

Download the latest newsletter here, or register below for free copies.

Our focus is on supporting the fuel industry as it adapts to new opportunities and challenges. By leveraging our experience and expertise in different markets, we create the reliable, highly functional and extremely competitive packages our customers demand. Our strength is our knowledge of fuel and how to improve fuel performance for different applications.

This always keeps us one step ahead of our competitors. Our products are tried and tested in many different environments whether at sea, on the road or in the air. With a worldwide network spanning 23 countries and 2000 employees, we can deliver global solutions geared to local customer needs.

North P&I Club is a leading marine mutual liability insurer providing P&I, FD&D, war risks and ancillary insurance to 147 million GT of owned tonnage and 60 million GT of chartered tonnage (at February 2019).

Download Option 1 Download Option 2 Download Option 3UK refineries are in good shape ahead of the looming sulfur spec change, which is set to cripple crack spreads on fuel oil and send middle distillate profits soaring.

Read NowThere is much noise these days surrounding IMO2020 and its effect on the commercial shipping sector moving forward.

Read NowThe captain of a cruise ship found to be burning fuel with excessive sulphur levels has been fined €100,000 (£88,500) in a Marseille court, the first such ruling in France.

Read NowEveryone has a perspective on the direction and outcome of the forthcoming IMO 2020 regulations from the refiners to the vessel operators and everyone in between within the supply chain.

Read NowMichael Banning of Innospec highlights the importance of rigorous onboard fuel storage system preperation well in advance of IMO 202, including tank cleaning and the use of additives.

Read NowInnospec is at the forefront of developing fuel performance and stability technology and bringing it to market, we have decades of experience bringing additive solutions to every part of the of the oil market from well to wheel. Innospec have developed OctamarTM HF-10 PLUS specifically for VLSFO to protect vessels and crew in a changing world.

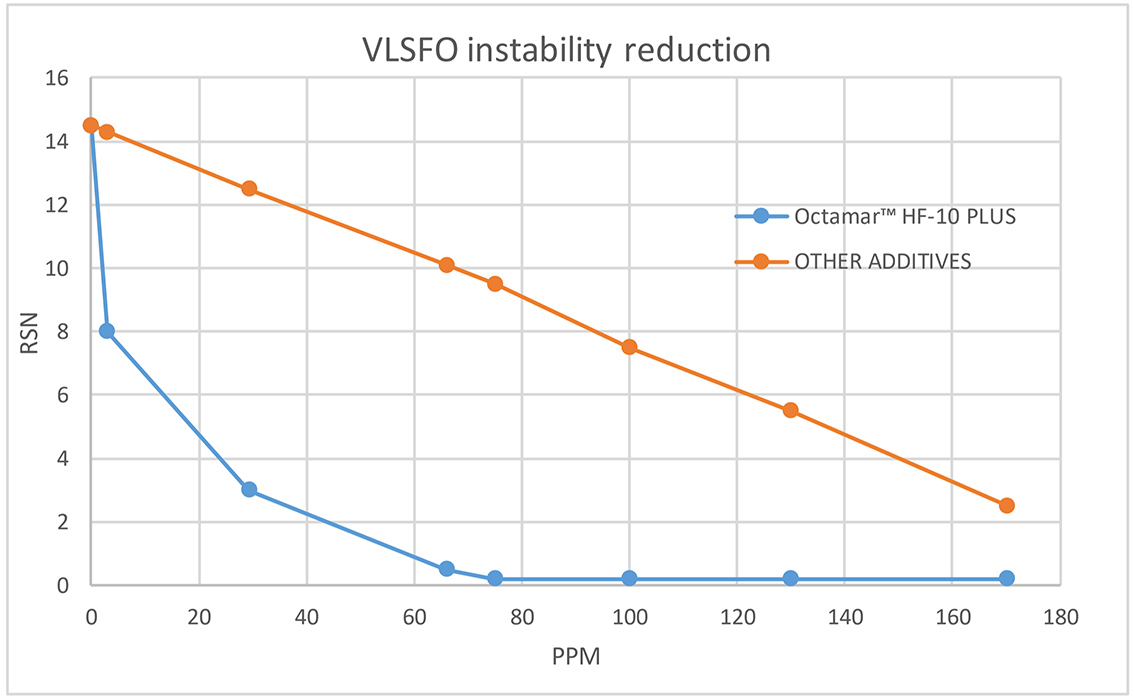

RSN (Reserve Stability Number) is the most reliable measure for predicting fuel handling issues on board, every major marine fuel testing lab around the world uses RSN as a verification tool against problem fuels. It is broadly accepted that fuels with RSN above 3 represent a real risk of fuel instability.

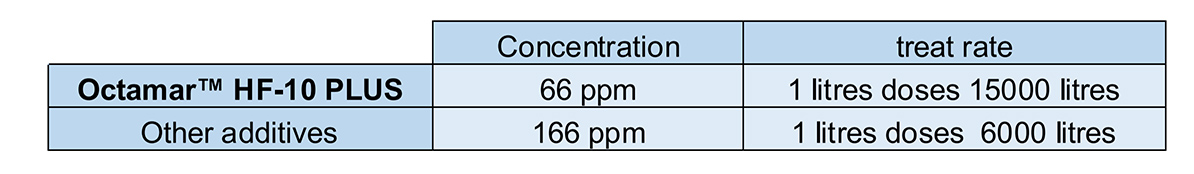

Based on our tests OctamarTM HF-10 PLUS is the best available technology, performing faster and at much lower dose rate than competing brands as illustrated above.